OVEN PANELS

OVEN PANELS are constructed of standard tongue and groove satin sheets. The panel channel that holds the inside and outside skins together is specially constructed to minimize heat transfer from the inside to outside panel. This type of panel construction provides great rigidity and strength and allows a minimum of heat loss by conduction through the panel seams.

Standard Features include:

- 20 ga. Satin Coat steel interior and exterior skins

- 4 lb. density insulation which is pre-formed, mineral-fiber felt

- Self-supporting, formed tongue and groove construction

- Satin Coat steel headers, slotted to minimize heat transfer

- Panels are banded and skidded for ease of shipping and handling

Optional items include:

- Custom panel widths

- Complete trim packages

- Profile openings and cutouts

- Fiberglass insulation, cut to width for insulating joints and corners

- 6 lb. density insulation

- Oven ductwork, diffusers

- Hinged access doors with handles & latch

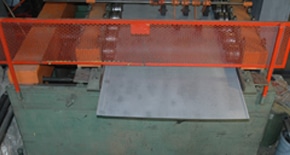

BRADLEY ROLL FORMER

- Custom width and Custom Lengths

- 20 ga

SPOT WELDER

- 25kva hand held spot welder

- Capable of spot welding 1/4” angle iron